Classify

- Designing ability

- Manufacturing process

- Test ability

- System Certification

Manufacturing process

MANUFACTURED

Mold technology

The company has the ability to open and make molds, and has a professional mold master. In the development and test phases, professionals are carefully, carefully, patiently and personally.Personally follow up and debug the product process until the product is mass-produced. Auxiliary equipment includes grinder, milling machine, lathe, wire cutting and other processing equipment, which fully meets the needs of processing spare parts in the first time and meets production needs. Reach the customer's delivery date!

The company has the ability to open and make molds, and has a professional mold master. In the development and test phases, professionals are carefully, carefully, patiently and personally.Personally follow up and debug the product process until the product is mass-produced. Auxiliary equipment includes grinder, milling machine, lathe, wire cutting and other processing equipment, which fully meets the needs of processing spare parts in the first time and meets production needs. Reach the customer's delivery date!

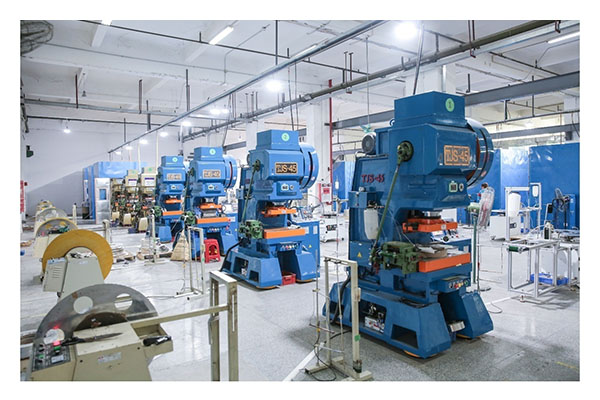

Precision stamping

The company’s stamping workshop introduces more than 50 domestic and imported high-speed precision punches, complete equipment, and a sound workshop management system. It specializes in the production of various sheet material processing, precision metal brackets, precision shields, precision terminals, and precision drawing parts. Production. At the same time, online cleaning, online inspection and packaging of products can be integrated. We have established cooperative relations with many first-class enterprises at home and abroad! We have realized high-efficiency and quality-guaranteed precision hardware processing services.

The company’s stamping workshop introduces more than 50 domestic and imported high-speed precision punches, complete equipment, and a sound workshop management system. It specializes in the production of various sheet material processing, precision metal brackets, precision shields, precision terminals, and precision drawing parts. Production. At the same time, online cleaning, online inspection and packaging of products can be integrated. We have established cooperative relations with many first-class enterprises at home and abroad! We have realized high-efficiency and quality-guaranteed precision hardware processing services.

Precision slitting

The company's slitting workshop introduces 5 domestic and imported high-precision slitting machines, fully equipped, and a sound workshop management system. It specializes in the slitting supply of various sheets. The materials include: nickel silver, phosphorous brass, beryllium copper, titanium copper, Special copper alloy, stainless steel, etc. The company has strong technical personnel. The slitting master has 20 years of professional slitting work experience, diligent and enthusiastic, superior technology, serious responsibility, quality assurance, and has a leading advantage in the industry. Material thickness can be achieved, (0.02--0.03--0.04--0.05-------1.00--2.00) etc.

The company's slitting workshop introduces 5 domestic and imported high-precision slitting machines, fully equipped, and a sound workshop management system. It specializes in the slitting supply of various sheets. The materials include: nickel silver, phosphorous brass, beryllium copper, titanium copper, Special copper alloy, stainless steel, etc. The company has strong technical personnel. The slitting master has 20 years of professional slitting work experience, diligent and enthusiastic, superior technology, serious responsibility, quality assurance, and has a leading advantage in the industry. Material thickness can be achieved, (0.02--0.03--0.04--0.05-------1.00--2.00) etc.

With a daily production capacity of 15 tons, more than 20,000 tons have been shipped so far

Dimension tolerance: within ±0.03mm

Minimum width: 3mm

The thinnest material: 0.05mm

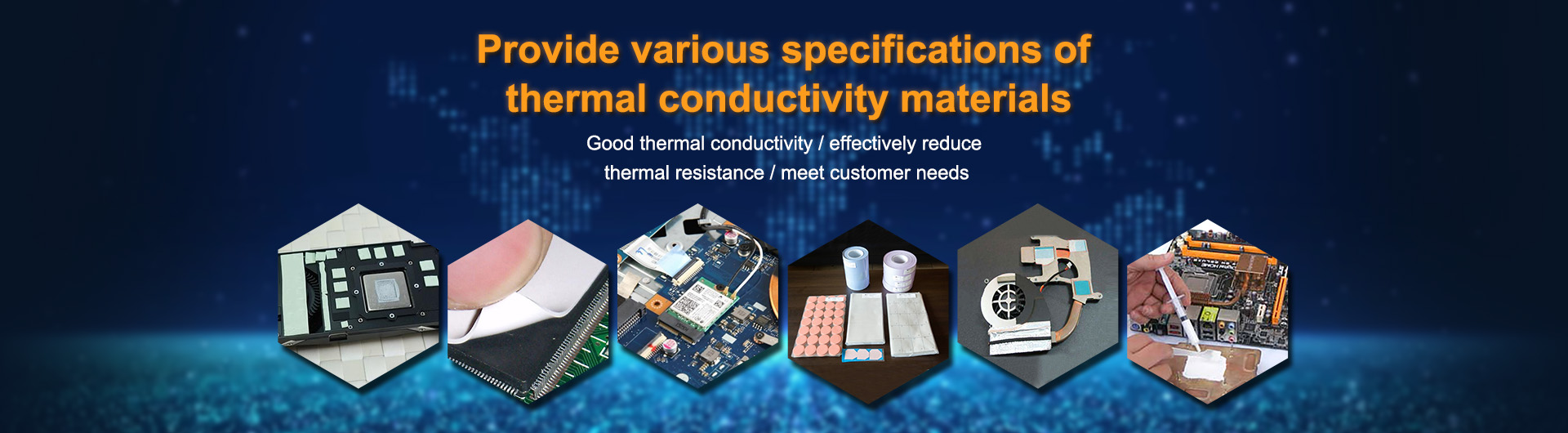

The company has a number of thermal material production equipment, automatic coating production lines and perfect testing instruments, and can produce various thermal products: high thermal conductivity silicone sheet, thermal graphite sheet, thermal double-sided adhesive, thermal conductive potting glue, thermal conductive silicon film, oxidation Thermal management interface materials such as aluminum thermally conductive ceramic sheets, silicon carbide ceramic heat sinks, phase change materials, thermally conductive silicone caps, thermally conductive silicone grease, thermally conductive silicone, and insulating particles. 4 thermally conductive product production lines

The daily capacity of thermal pads is 3,500 square meters, the daily capacity of thermal gel is 150,000 cc, the daily capacity of thermal grease is 2 tons, and the daily capacity of thermally conductive potting glue is 5 tons.

1. Low oil yield and low thermal resistance,

The maximum thermal conductivity is 15 watts;

2. The thinnest thickness can be compressed to 0.08mm

3. The performance is equivalent to that of Dow and Laird products.