Classify

- Etching products

- Pre-plated material

Coated products

Single-sided coating insulating base material

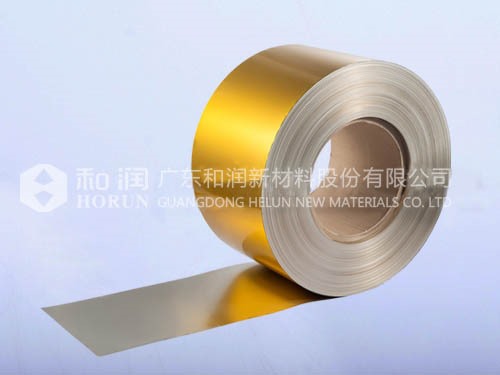

Under the premise of current shortage of human resources and increased market costs, various material manufacturers need to reduce costs and realize early coating on materials, which significantly reduces the cost of intermediate processors and end customers, and is better than the original manual pasting function. And higher performance.

A new type of process in the field of insulation and shielding: white copper single-sided and partially coated high-temperature insulating materials, single-sided coated insulating materials can be directly stamped, and partially coated insulating materials can be positioned according to customer drawings. Partially coated insulating materials, customers can take It can be directly assembled after stamping the material strip, eliminating several processes. This process is fully in line with the ROSH PROS PFAS specification. It is mainly used for metal surfaces that require insulation and shielding. It is suitable for mobile phones, computers, navigators, walkie-talkies and other related signals. Communication industries such as transmitting and receiving.

Advantages of the new process:

1. Continuously electroplating a layer of high-temperature insulating film on the surface of the raw material, stamping and forming, and the finished product can be produced after cleaning, eliminating the "sticking" process;

2. The color of the film has a good sensory effect, currently there are two effects of golden yellow and black, the film thickness is controlled between 15-25um, and the salt spray is 24H;

3. High temperature resistance of 260 degrees for 10 minutes, while ensuring the excellent soldering performance of nickel silver, partial coating insulation material withstand voltage test 300 volts will not break down under the condition of 1 minute, single-sided coating insulation material withstand voltage test 500-800 volts No breakdown in 1 minute;

4. During the stamping process, the film will not burst or fall off, it has good bonding force and excellent electrical properties;

A new type of process in the field of insulation and shielding: white copper single-sided and partially coated high-temperature insulating materials, single-sided coated insulating materials can be directly stamped, and partially coated insulating materials can be positioned according to customer drawings. Partially coated insulating materials, customers can take It can be directly assembled after stamping the material strip, eliminating several processes. This process is fully in line with the ROSH PROS PFAS specification. It is mainly used for metal surfaces that require insulation and shielding. It is suitable for mobile phones, computers, navigators, walkie-talkies and other related signals. Communication industries such as transmitting and receiving.

Advantages of the new process:

1. Continuously electroplating a layer of high-temperature insulating film on the surface of the raw material, stamping and forming, and the finished product can be produced after cleaning, eliminating the "sticking" process;

2. The color of the film has a good sensory effect, currently there are two effects of golden yellow and black, the film thickness is controlled between 15-25um, and the salt spray is 24H;

3. High temperature resistance of 260 degrees for 10 minutes, while ensuring the excellent soldering performance of nickel silver, partial coating insulation material withstand voltage test 300 volts will not break down under the condition of 1 minute, single-sided coating insulation material withstand voltage test 500-800 volts No breakdown in 1 minute;

4. During the stamping process, the film will not burst or fall off, it has good bonding force and excellent electrical properties;